Strategies for Effective Leadership Development

Effective leadership development can mean the difference between creating invested, knowledgeable managers who can direct companies toward that next level of growth and derailing operations and souring the culture you’ve built.

McKinsey & Company conducted a study that distills the 4 main reasons why leadership development programs fail:

- Not allowing for context,

- Not linking development programs to real world projects,

- Underestimating what it really takes to change behaviors, and

- Not measuring results.

There are several leadership development methods, but results are what really matter. Learn how you can develop better leaders below.

- 1. Join a Peer Advisory Group

- 2. Focus on Continuous Learning

- 3. Set Clear Leadership Goals

- 4. Build Emotional Intelligence

- 5. Develop Effective Communication

- 6. Identify Skill Gaps

- 7. Learn to Delegate

- 8. Motivate Employees

- Wrapping Up: Effective Leadership Development Methods

1. Join a Peer Advisory Group

Peer advisory groups provide much-needed context for participants, and they allow group members to help shape the course of their own development. By creating a forum for open and honest discussion among leaders, companies are leveraging the knowledge that already resides on the team. In doing so, the conversation becomes the content, and the team benefits from the experience and context from each other. Below are some of the ways joining a leadership advisory group can help develop effective leaders.

Real-world projects

Peer advisory groups that are rooted in real discussions about the most challenging issues help cross-functional teams tackle real business problems. Rather than relying on case studies or theoretical content, peer groups bring their own topics to the table to generate ideas and feedback from their colleagues. Peer groups help leaders see the blind spots and unintended consequences of their actions, which helps align the entire team towards major business objectives.

Behavioral change

There’s just something about the inherent accountability that comes with publicly committing to an action in a peer group setting. Peer groups that hold each other accountable are more likely to influence actual behavioral change. This type of “action learning” can increase retention of key ideas by more than six times, which will accelerate behavioral change faster than a traditional training program.

Ongoing peer advisory groups can help participants identify what the McKinsey authors call “below the surface” thoughts, feelings, assumptions, and beliefs. A professionally facilitated group can uncover many of the underlying reasons behind a person’s actions, which helps illuminate a path for real change. Plus, a group that meets regularly will begin to see improved relationships (strong social ties have been proven to increase innovation), and they’ll get better at the peer advisory process over time.

ROI you can measure

The McKinsey authors found that companies pay lip service to the importance of effective leadership development but have no evidence to quantify the value of their investment. Measuring the return on leadership development programs may not be easy, but the authors point out a few ways to demonstrate the value that that comes from executive development. Measuring promotion rates, retention of key leaders and employee engagement scores can help demonstrate the value of the program.

Research has shown that organizations that include peer advisory groups as part of their executive development mix will enjoy a higher return on their investment. As the group tackles real company issues, provides context for each other, and shows a real change in behavior, program sponsors will understand the value of their investment.

2. Focus on Continuous Learning

When you’re a leader, you’re never finished learning. Continuous learning allows you to keep growing and evolving as a leader, adding new skills to your repertoire.

Staying up-to-date on the latest industry trends is a key benefit of continuous learning. Leadership is complex and requires a diverse array of skills, and those skills are constantly changing. As a leader, you should be taking advantage of networking events and workshops that can help you stay up to date.

Continuous learning is one of the key benefits of peer advisory groups. Connecting with executives across industries can help you get a better understanding of how leaders operate from different perspectives.

3. Set Clear Leadership Goals

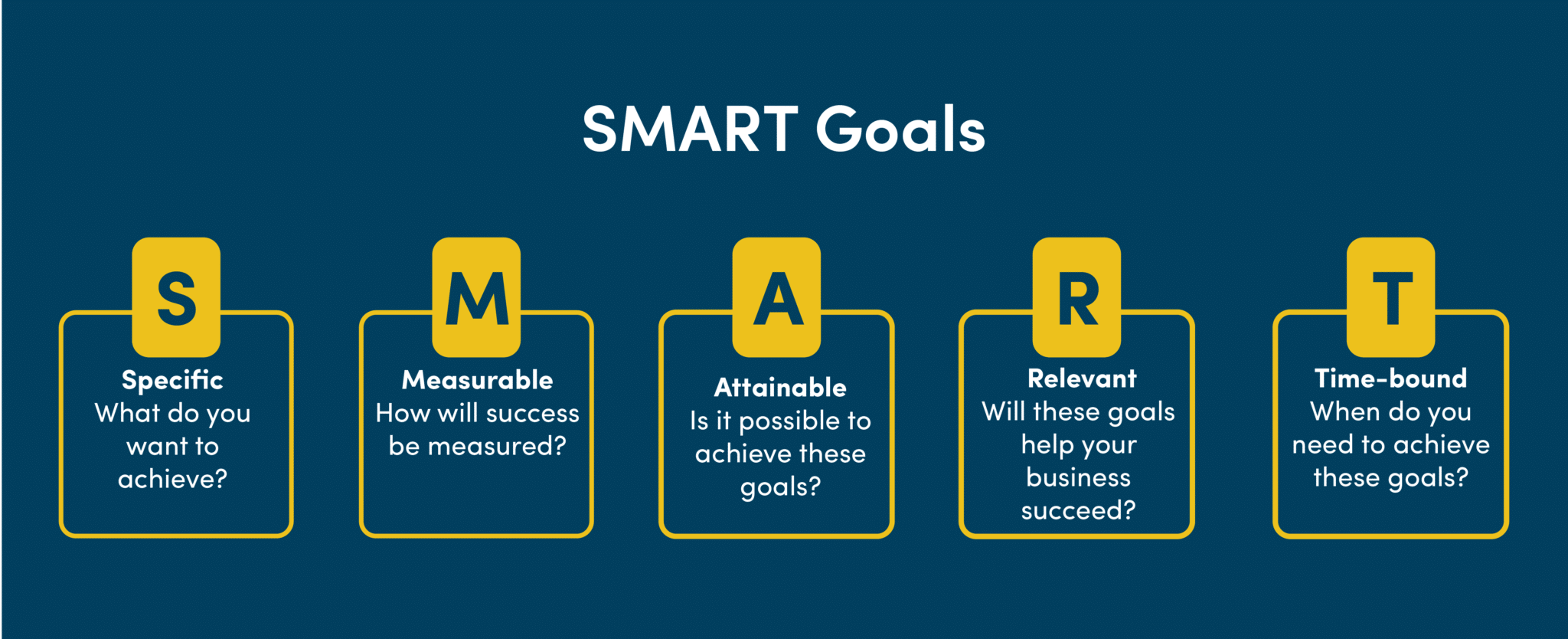

As a leader, setting goals helps you stay on track and work toward larger objectives. Setting SMART goals — or goals that are Specific, Measurable, Achievable, Relevant, and Time-Bound — can help you be a better leader.

Setting specific goals helps you create milestones that make a difference in your organization. Your goal might be to create a better work-life balance for employees or to focus on building relationships with customers in new markets. As long as you’re working toward a goal that leads to measurable results, you’re off to a good start.

When you’re setting leadership goals, make sure those goals are beneficial to your team and your organization as a whole. Keeping everyone on track with clearly defined goals is one of the most important parts of effective leadership development.

4. Build Emotional Intelligence

There are certain leadership qualities that all good leaders share, such as emotional intelligence. Emotional intelligence is how you process and deal with emotions — including how you perceive, interpret, use, and manage emotions. A good leader needs to be able to understand others and manage their own emotions. Emotionally intelligent leaders are active listeners with empathy and self-awareness, allowing them to connect with team members and build real relationships.

As a leader, you need to be able to manage your emotions as well as the emotions of your team members. Emotional intelligence plays a key role in conflict resolution, allowing you to empathize with both sides and find a mutually beneficial solution.

It’s also important for leaders to manage their emotions because a leader’s emotions can affect the rest of the team. Learning how to control your emotions is key — especially during stressful times.

5. Develop Effective Communication

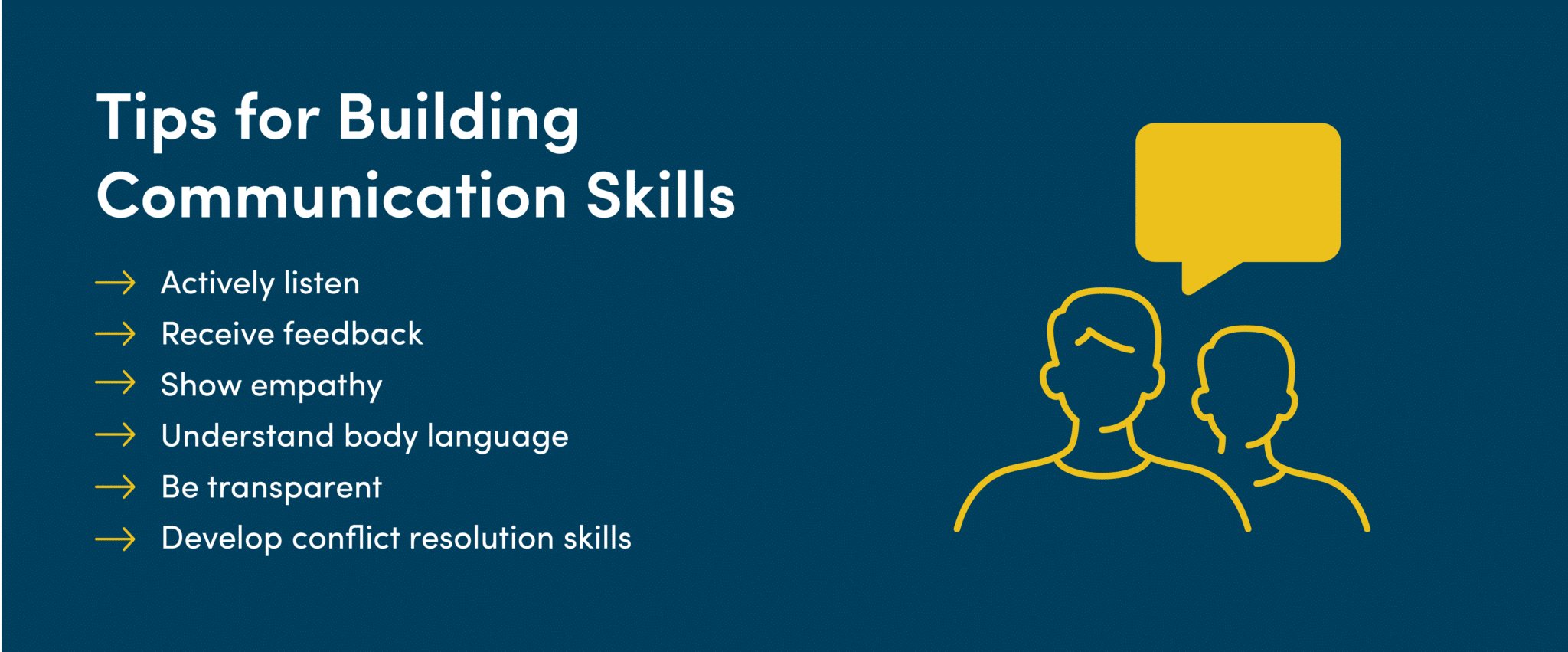

Communication is one of the biggest parts of leadership, and it’s not all about making passionate speeches or giving instructions. When you’re in a leadership position, you need to be able to clearly communicate both ways — by talking and listening.

You can work on your communication skills by taking the time to actively listen to your team. Active listening involves listening with the intent of understanding. Instead of simply listening to the words someone says, you need to process their non-verbal messages as well. When someone is finished speaking, your response should provide feedback on what they said.

Listening to feedback from others is also a part of effective leadership development. You need to be able to communicate with the people around you, and the best way to do that is to get feedback so you can improve.

6. Identify Skill Gaps

Decision-making skills are a necessity for good leaders. To be a leader, you need to decide what you’re good at and where you fall short, and the same goes for your team. Nobody excels at everything, which is why identifying skills gaps and figuring out how to fill them is such a critical job.

If there’s something you can’t do as a leader, you need to find an alternative solution. Maybe you lack certain organizational skills, or maybe you’re not good at clearly expressing your thoughts through writing. Every individual and organization has skill gaps, and it’s up to you to identify those skill gaps and work to fill them by delegating wisely.

Skill gaps take many forms. Being proactive in identifying and filling skill gaps helps your organization stay on track.

7. Learn to Delegate

You can’t do everything on your own, which is why learning to delegate is a huge part of effective leadership development. If you want to become a better leader, you need to learn how to empower the people around you by delegating.

Delegating is important for two reasons: It motivates and empowers team members while spreading the workload across the team. Motivation is what encourages people to wake up and go to work every day, but it can be hard to feel motivated when you’re not playing an important role. While people like having responsibilities to motivate them, too many responsibilities can be overwhelming. Delegating allows you to find the perfect balance between too little and too much work, which helps you keep everyone engaged and satisfied in their roles.

8. Motivate Employees

At the end of the day, your job as a leader is to motivate your team to work toward a common objective. Working hard is difficult when you’re not motivated, and every motivated team starts with a good leader.

Every leadership development plan should include learning how to better motivate employees. You want employees to feel a sense of purpose at work, and that’s not always easy to accomplish. A leadership advisory group can give you a chance to learn about different motivational strategies from leaders across various industries.

When your employees are motivated, they put more energy and effort into the task at hand.

Wrapping Up: Effective Leadership Development Methods

Effective leadership development doesn’t happen overnight, but it does play a crucial role in successful organizations. Successful leaders manage successful teams, while poor leadership qualities can be the demise of an organization.

Peer advisory groups are one of the most effective leadership development methods. Vistage’s peer advisory groups can help leaders get a better perspective on leadership and the qualities that make successful leaders. If leadership development is an area where your organization is lacking, contact Vistage to learn more about the benefits of our peer advisory groups and executive coaching programs.

Category : Leadership

Tags: leadership development, Peer Advantage, peer advisory, peer advisory groups